DCS Joins Metrologic and ZeroTouch at IMTS to Showcase Universal Metrology Solutions

Dimensional Control Systems partners with other Sandvik Group companies to deliver true end-to-end metrology solutions at IMTS 2024

As a part of Sandvik Group, all three companies share a common link, fomenting new levels of cooperation that have taken advantage of Quality 4.0 to interconnect traditionally siloed elements of manufacturing, allowing manufacturers to drive quality downstream from earlier design and development. Utilizing Quality 4.0 and QIF, a storage framework for product manufacturing information (PMI), this new solution harnesses the true power of CAD to allow each step of the product life cycle to take advantage of the work done before. This relieves the need for constant re-engineering, development, and interpretation at each step of the manufacturing process by using a one true source of information, and allowing all parties to use the same source, thus unifying your organization around a single vision and process.

This new solution begins in design by testing, simulating, and optimizing the CAD data, pulling in other elements from FEA, dimensional analysis, and engineering to create a true digital twin of the product. This digital twin can be interacted with and tested as if it were a physical prototype in order to validate production methods, assembly processes, machine capability, and environmental storage. Harnessing PMI embedded in the CAD, metrology and manufacturing can pull straight from the source to develop measurement and inspection plans, cutting programs, assembly processes, and quality checks. From here, the solution provides quality data management to monitor all these processes in real-time, while delivering up to date information for decision making, root cause analysis, and corrective actions.

At IMTS 2024, this combined solution comes together in the real world, showcasing the power of Sandvik Metrology solutions to simply manufacturing by making the process easier, connections between software simpler, and leveraging advanced systems to tackle complex problems.

"The combination of Sandvik Metrology Group technology allows for a seamless solution like never before, with DCS bookending the process with design engineering technology and quality data management, Metrologic’s high end metrology software and inspection devices, and then complemented by ZeroTouch inspection, this new end-to-end solution provides a single source of quality for manufacturers.” Said Thagu Vivek, Director of Quality Data Management (QDM) Solutions. “As a universal solution, manufacturers do not need to replace existing equipment, but can instead incorporate it to get real value out of legacy technology while being able to tap into new advancements. This makes it economical, as well as impactful, for both small and large manufacturers regardless of size or number of locations.”

Join DCS, Metrologic Group, and ZeroTouch at IMTS this year in Booth 134728, in the East Building Level 3 Quality Pavilion to get a tour of the complete solution, and see how it can help you in part or in whole. Can’t make the event? Join our newsletter for upcoming webinar announcement to see the solution piece by piece through a virtual showcase series coming soon.

About Dimensional Control Systems

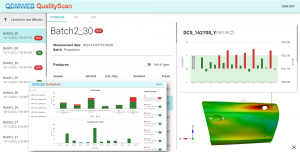

DCS, a SANDVIK company, provides two software systems as well as dimensional engineering services and GD&T consulting. The two software systems, 3DCS Variation Analyst – CAD integrated app used to simulate dimensional variation with the Digital Twin, and QDM SPC Platform – used to collect, standardize, and report measurement data in real-time as dashboards, reports, and charts, combine together to provide an end-to-end solution for design to production. Learn more at 3dcs.com.

Benjamin Reese

Dimensional Control Systems

+1 2482699777

email us here

Visit us on social media:

Facebook

X

LinkedIn

YouTube

Other

QDMWEB QI provides the backbone for your quality solution, empowering you to stay up to date on real time quality metrics, potential issues, and find solutions

Distribution channels: Automotive Industry, Aviation & Aerospace Industry, Conferences & Trade Fairs, Electronics Industry, Manufacturing

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release