DCS Celebrates 30 Years of Dimensional Management and Quality Improvement

From humble beginnings to industry-leading solutions, Dimensional Control Systems marks three decades of innovation and excellence.

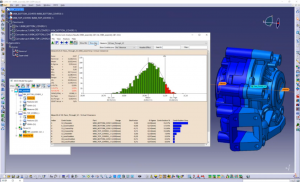

DCS began as a dimensional engineering services provider, primarily serving automotive manufacturers. Early on, the team recognized a critical gap in tools capable of meeting the rigorous demands of analysis and design. This need drove the development of 3DCS Variation Analysis Software, which quickly became a cornerstone for manufacturers. Integrated into Dassault Systèmes' CATIA platform, 3DCS soon gained traction in aerospace and expanded into industries like medical devices, electronics, consumer goods, and machinery.

Simultaneously, the QDM (Quality Data Management) Suite emerged from its roots as a simple reporting tool for 3DCS. Evolving into a robust quality management system, QDM now supports thousands of users, streamlining data collection, reporting, and decision-making. Innovations like the DataGrabber have automated data acquisition, empowering organizations with actionable insights through shared dashboards and analytics.

Over three decades, DCS has evolved alongside its leadership. Founders Robert Kaphengst, a pioneer in GD&T and dimensional engineering, and John Mathieson, an engineering veteran from General Motors, guided DCS through transformative growth. Now under Sandvik's Metrology Group, the company is led by Michael Ulicny, an original DCS team member with deep expertise in dimensional engineering. Through collaborations with advanced technology firms like Metrologic Group, DCS continues to advance Quality 4.0 initiatives, seamlessly connecting design, production, and inspection processes.

With its flagship solutions—3DCS and QDM—DCS empowers manufacturers to simulate designs, leverage inspection data, and drive continuous improvement across the product lifecycle. By integrating additional technologies from Sandvik, DCS strengthens its ability to deliver interconnected tools that optimize quality management and operational efficiency.

“Dimensional engineering has evolved significantly as a science,” said Michael Ulicny, DCS President, “and DCS is proud to have played a key role in advancing its application through innovative, effective tools.”

As DCS celebrates this milestone, join the journey by subscribing to the DCS Newsletter and exploring the blog at 3dcs.com. Throughout the New Year, DCS will feature stories, interviews, and retrospectives on its founding, technological advancements, and the people who made it all possible.

About Dimensional Control Systems (DCS)

As a proud member of the Sandvik Group, Dimensional Control Systems (DCS) delivers cutting-edge software solutions designed to help manufacturers optimize their designs for production, ensure quality throughout manufacturing, and identify and resolve production challenges. Integrated with other Sandvik solutions, DCS tools enable streamlined, end-to-end quality processes, supporting model-based definition from initial design to final production. Trusted by leading manufacturers in industries such as aerospace, automotive, medical devices, electronics, and energy, DCS solutions have consistently driven significant improvements in lead times and production yields.

Discover more at 3dcs.com and Sandvik Manufacturing Solutions.

Benjamin Reese

Dimensional Control Systems

email us here

Visit us on social media:

Facebook

X

LinkedIn

YouTube

Other

Distribution channels: Automotive Industry, Aviation & Aerospace Industry, Consumer Goods, Electronics Industry, Manufacturing

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release